Used Remediation Systems Available for Lease or Purchase

Below you will find a summary of used systems currently available for purchase or lease from PTS. Most systems can be modified to include more or less SVE and/or sparge legs or other options as needed. PTS can supply detailed photos, drawings, and specifications for each system upon request. All of the systems listed below were designed and constructed by PTS and can be supplied with O&M manuals and control system documentation.

When used systems come back to us, they typically are in need of some level of clean-up and refurbishment. Once we find a system that is a potential fit for a customer, we determine if any system modifications need to be completed to meet customer’s site specific requirements. In addition, PTS staff complete a thorough inspection of the system to determine if any major or minor equipment repairs are needed. Following evaluation of costs for any needed repairs/modifications, PTS will provide a quotation to customer for purchase or lease of a system. Following signing of a purchase or lease agreement, all needed repairs and modifications will be completed and the system will receive a thorough cleaning. Recommended routine equipment maintenance tasks are then completed including replacing blower oil, greasing blowers/motors, and replacing all blower and building air filter elements. Following system clean-up/refurbishment, a full system start-up/shake-down is performed, during which proper operation of all blowers, process instrumentation gages/sensors, and control systems are verified and documented.

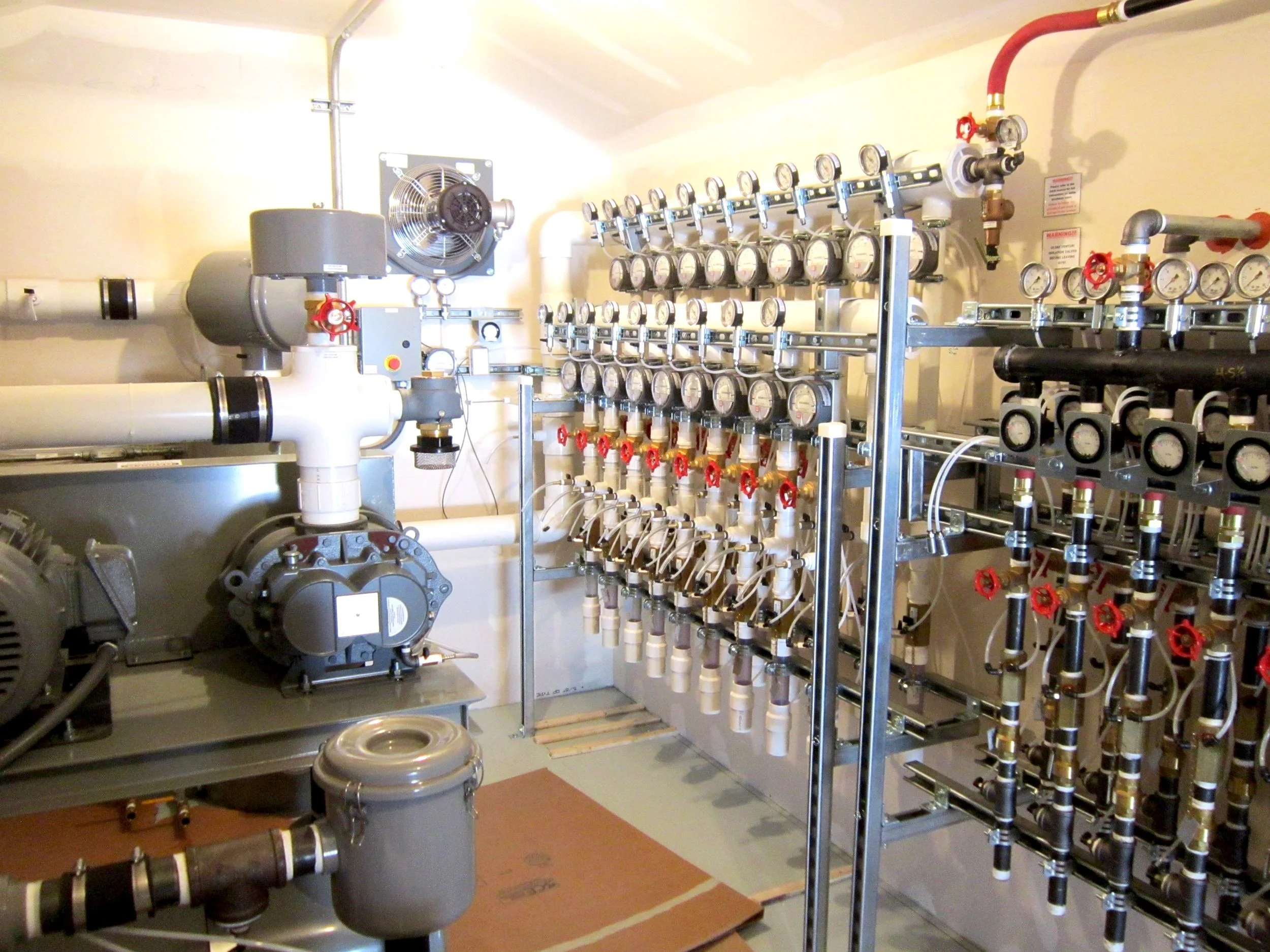

PTS System #2 - Turnkey SVE and Sparge System

SVE Specifications:

Dresser Roots URAI-33 rotary lobe positive displacement vacuum blower powered by 7.5 HP electric motor

Up to seven (7) SVE extraction legs with control valves, flow gauges, and vacuum gauges

70 gallon knock-out tank with high-level float switch

Air Sparge Specifications:

Rietchle DTA-80 rotary vane blower powered by 7.5 HP electric motor

Up to eight (8) sparge legs with control valves, flow gauges, and pressure gauges divided between three zones

6-foot fin-tubed pipe section passive heat exchanger for sparge blower discharge

2-inch sparge manifold divided into two (2) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface and cellular-based telemetry system

Blower, vacuum, and pressure transmitters for real time monitoring and data logging

8-foot wide x 10-foot long shed enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 120/240 vac power supply

PTS System #6 - Skid Mounted Air Sparge System

Air Sparge Specifications:

Rietchle DLR-100 claw blower powered by 5 HP electric motor with VFD controller

Active forced-air heat exchanger to cool sparge blower discharge

2-inch sparge total flow venturi and magnehelic flow gauge (scfm) and discharge pressure gauges

2-inch female camlock for connection to customer supply-piping

General System Details:

Electro-mechanical control panel

Stand-alone sparge blower system mounted on 34" wide x 72” long steel skid

System power requirements - 30 amp, single phase, 240 vac power supply

PTS System #16 - Turnkey SVE and Sparge System

SVE Specifications:

Dresser Roots URAI-47 rotary lobe vacuum blower powered by 7.5 HP electric motor with VFD controller

Three (3) SVE extraction legs with control valves, flow gauges, and vacuum gauges (plus two spare legs)

70 gallon knock-out tank with automatic transfer pump

Air Sparge Specifications:

Rietchle C-DLR-150 claw blower powered by 10 HP electric motor with VFD controller

Seven (7) sparge legs with control valves, flow gauges, and pressure gauges

Active forced-air heat exchanger for sparge blower discharge

2-inch sparge manifold divided into two (2) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface, configured for interlocks with Falmouth electric catalytic oxidizer (catox) unit, configured for remote telemetry monitoring and control (requires hi-speed internet connection)

10-foot wide x 18-foot long enclosure partitioned into classified and non-classified area used with control room, insulated, drywalled, heated, and ventilated

System power requirements - 200 amp, 3 phase, 120/240 vac power supply

PTS System #18 - Turnkey SVE and Sparge System

SVE Specifications:

Rietchle SAP-430 regenerative vacuum blower powered by 8.5 HP electric motor with VFD controller

Nine (9) to eleven (11) SVE extraction legs with control valve, flow gauges, and vacuum gauges

55 gallon knock-out tank with high-level float switch

Air Sparge Specifications:

Rietchle DLR-100 claw blower powered by 7.5 HP electric motor

Eleven (11) sparge legs with control valves, flow gauges, and pressure gauges divided between two zones

Active forced-air heat exchanger for sparge blower discharge

2-inch sparge manifold divided into two (2) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface (cellular-based telemetry system can be added upon request)

8-foot wide x 14-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 208/120 vac power supply

PTS System #20 - Turnkey SVE and Sparge System

SVE Specifications:

Dresser Roots URAI-59 positive displacement blower powered by 20 HP electric motor with VFD controller

Four (4), 2.5-inch SVE extraction legs with control valves, flow gauges and vacuum gauges, and one (1), 3-inch SVE extraction line with slide gate valve for connection to remote extraction hub (supplied by others)

120 gallon knock-out tank with high-level switch

Air Sparge Specifications:

Rietchle DLR-150 claw blower powered by 10 HP electric motor with VFD controller

Three (3), 2-inch sparge legs with control valves, flow gauges, and pressure gauges, each with solenoid-controlled timers, and one (1), 2-inch sparge leg to feed a remote sparge hub (supplied by others)

Active forced-air heat exchanger for sparge blower discharge

General System Details:

PLC-based control panel with touch screen interface (cellular-based telemetry system can be added upon request) configured to operate with Falmouth Falco 300 catalytic oxidizer

10-foot wide x 16-foot long enclosure partitioned into a Class 1, Div. 2 area for equipment and non-classified area for system control panel - insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 120/240 vac power supply

PTS System #25 - Turnkey SVE and Sparge System

SVE Specifications:

Dresser Roots URAI-47 rotary lobe blower powered by 10 HP electric motor

Fourteen (14), 1.5-inch SVE extraction legs with control valves, flow gauges, and vacuum gauges

110 gallon knock-out tank with 75 gallon capacity at high-level float switch

Air Sparge Specifications:

Rietchle DLR-100 claw blower powered by 7.5 HP electric motor

Nineteen (19) sparge legs with control valves, flow gauges, and pressure gauges split amongst three (3) zones each with solenoid-controlled timers

American Industrial ACA 3182 active forced-air heat exchanger for sparge blower discharge

General System Details:

UL 508A/698A listed control panel with PLC controller and HMI touchscreen interface (cellular-based telemetry system can be added upon request)

10-foot wide x 14-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 120/240 vac power supply

PTS System #4 - Turnkey SVE and Sparge System

SVE Specifications:

Rietchle SAP 530 regenerative vacuum blower powered by 8.7 HP electric motor with VFD controller

Four (4) to eight (8) SVE extraction legs with control valves, flow gauges, and vacuum gauges

70 gallon knock-out tank with high-level float switch

Air Sparge Specifications:

Rietchle DTA-140 rotary vane blower powered by 10 HP electric motor

Total of eleven (11) sparge legs with control valves, flow gauges, and pressure gauges divided between three zones

6-foot fin-tubed pipe section passive heat exchanger for sparge blower discharge

2-inch sparge manifold divided into three (3) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface (cellular-based telemetry system can be added upon request)

Blower, vacuum, and pressure transmitters for real time monitoring and data logging

8-foot wide x 14-foot long shed enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 208/120 vac power supply

PTS System #14 - SVE and Biosparge/Oxygen Injection System

SVE Specifications:

Dresser Roots URAI-36 rotary lobe vacuum blower powered by 7.5 HP electric motor with VFD controller

Seven (7) SVE extraction legs with control valves, flow gauges, and vacuum gauges

60 gallon knock-out tank with high-level float switch

Biosparge/Oxygen Injection Specifications:

Three (3) oxygen manifold zones with timer-controlled solenoid valves

Total of nineteen (19) injection legs with control valves, flow gauges, and pressure gauges

Brass oxygen distribution system supplied with flow and pressure gauges

System to be connected to oxygen dewars (supplied by others)

General System Details:

Electro-mechanical control panel

8-foot wide x 10-foot long wooden enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 120/240 vac power supply

PTS System #17 - Turnkey SVE and Sparge System

SVE Specifications:

Dresser Roots URAI-45 positive displacement vacuum blower powered by a belt-driven 7.5 HP three-phase TEFC motor

Seven (7) SVE extraction legs with control valves, flow gauges, and vacuum gauges

110 gallon knock-out tank with 44 gallon capacity at high-level float switch

Air Sparge Specifications:

Rietchle DLR-100 claw blower powered by 7.5 HP electric motor

Nine (9) sparge legs with control valves, flow gauges, and pressure gauges

Active forced-air heat exchanger for sparge blower discharge

2-inch sparge manifold divided into two (2) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface and cellular-based telemetry system

8-foot wide x 12-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 208/120 vac power supply

PTS System #19 - Turnkey SVE and Sparge System

SVE Specifications:

AirTech 3BA1500 regenerative vacuum blower powered by 2.0 HP electric motor with VFD controller

Five (5) SVE extraction legs with control valves, flow gauges, and vacuum gauges

70 gallon knock-out tank with automatic transfer pump

Air Sparge Specifications:

Rietchle DLR-100 claw blower powered by 7.5 HP electric motor

Six (6) sparge legs with control valves, flow gauges, and pressure gauges divided between two zones. Expandable to up to eight (8) sparge legs.

Active forced-air heat exchanger for sparge blower discharge

2-inch sparge manifold divided into two (2) solenoid timer controlled valves

General System Details:

PLC-based control panel with touch screen interface (cellular-based telemetry system can be added upon request)

8-foot wide x 12-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, single phase, 120/240 vac power supply

PTS System #21 - Turnkey Biosparge/Oxygen Injection System

Biosparge/Oxygen Injection Specifications:

Kaeser Model SM-10 Air Center - rotary screw air compressor with 10 HP, 3 phase, 230/460 vac motor, capable of producing 33 scfm at 7,130 feet at 90 psig. Includes integral refrigerated air dryer, 70 gallon air receiver tank, and sound proof enclosure housing providing 66 dBa sound level.

Clean air treatment package including oil-coalescing filter and automatic drain

AirSep Model AS-D PSA oxygen generator capable of providing 90 SCFH of oxygen at 40 psig complete with integrated control panel to automatically control PSA process

60 gallon oxygen storage tank with 0-200 psi pressure gauge, -20 to 120 degree F temperature gauge, pressure safety valve, and pressure regulator to regulate oxygen pressure to distribution manifold.

Brass oxygen distribution system consisting of three (3) timer-controlled solenoid valves, supplying oxygen to three (3) brass manifolds consisting of a total of fourteen (14) injection lines, each with flow and pressure gauges

General System Details:

ULA 508A listed electro-mechanical control panel

8-foot wide x 10-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 120/240 vac power supply

PTS System #26 - Turnkey SVE and Sparge System

SVE Specifications:

AirTech Model 3BA1600 regenerative vacuum blower powered by 5 HP electric motor

Five (5), 1.5-inch SVE extraction legs with control valves, flow gauges, and vacuum gauges

70 gallon knock-out tank with 28 gallon capacity at high-level float switch and centrifugal transfer pump with 1.0 HP motor

Air Sparge Specifications:

Gardner Denver V-DTA-80 claw blower powered by 7.5 HP electric motor

Seven (7) sparge legs with control valves, flow gauges, and pressure gauges split between two (2) manifold zones each with solenoid-controlled timers, bleed air valve and silencer, and pressure gauge.

Six feet of passive fin-tubed heat exchanger for cooling sparge blower discharge

General System Details:

UL 508A/698A listed control panel with PLC controller and HMI touchscreen interface with cellular-based telemetry system

8-foot wide x 10-foot long enclosure insulated, drywalled, heated, and ventilated

System power requirements - 100 amp, 3 phase, 208/120 vac power supply